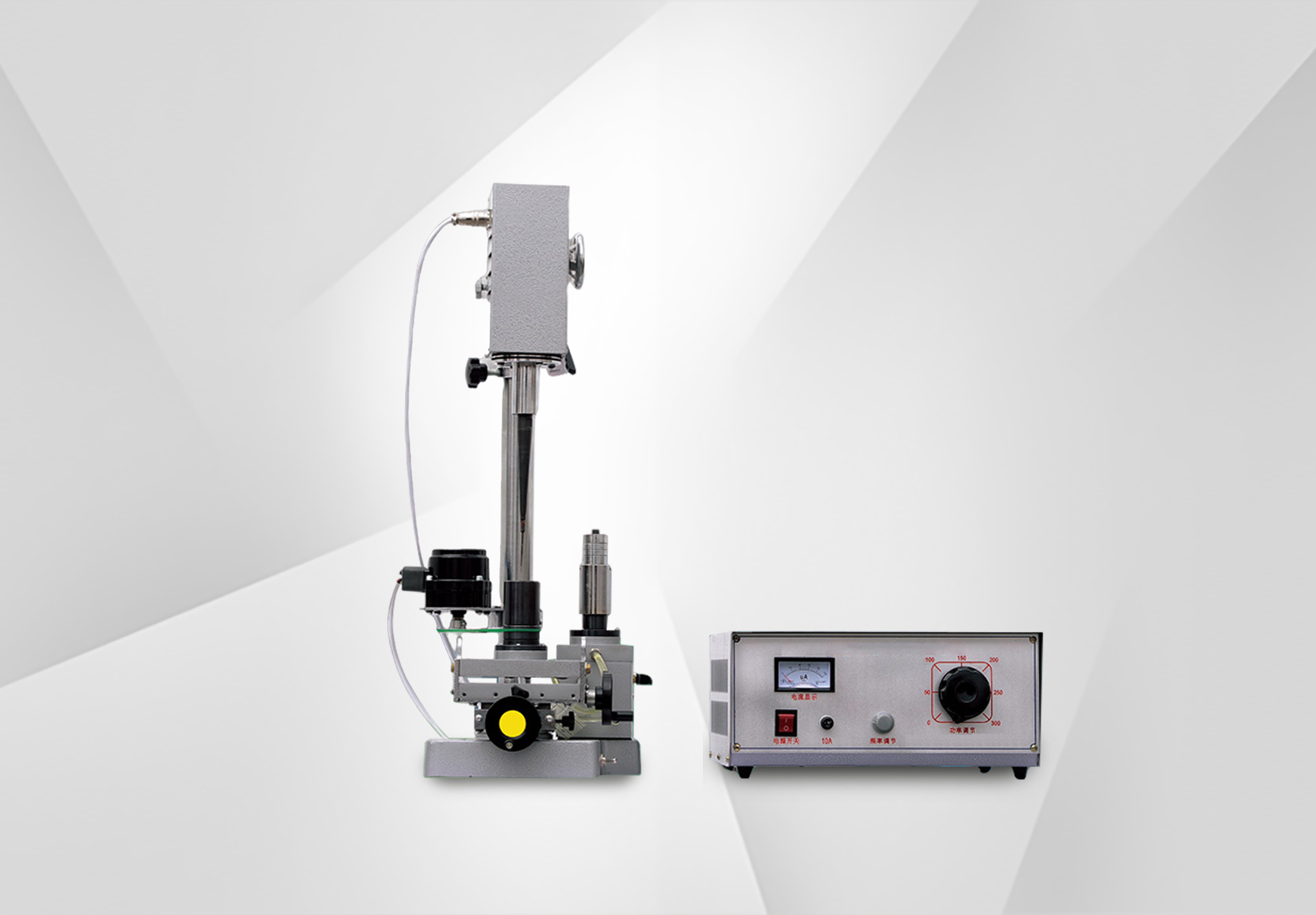

ROST80-100 Oil Return Ultrasonic Grinder

ROST80-100 Oil Return Ultrasonic Grinder

1.Preface

Ultrasonic wave is applied to the grinding and polishing of diamond and synthetic diamond drawing dies. This new technology has been widely used at home and abroad.

The processing speed and product quality of ultrasonic wave grinding and polishing have been greatly improved.

Upm-100 oil return type ultrasonic grinding machine is used for repairing and polishing diamond and synthetic diamond drawing dies in the range of 0.02 to 2.0 mm.

The major improvement of this machine is to upgrade the ordinary oil pressure, adopt the patented product oil return structure,

solve the problem of oil leakage, better maintain the working pressure and improve the production environment.

2.Technical Parameter

1. Input power: AC220 V, 50 Hz

2. Working frequency: About 20KHz

3. Power consumption: ≤ 150W

4. Transducer: Piezoelectric

5. Pressurization mode: hydraulic transmission, weight pressurization

6. Working speed: 48 rpm

3.Working Principle and Equipment Composition

1. This machine uses ultrasonic high-speed vibration to produce impact on the machined surface through steel needle and die material, grinding the machined surface to achieve the required shape and size.

2. The equipment is mainly composed of ultrasonic generator, transducer and color seat.

(1) Ultrasonic generator

The ultrasonic generator is installed in a small cabinet, which is an ultrasonic power supply. The frequency automatic tracking circuit is used to achieve the best ultrasonic output and vibration effect.

(2) Transducer

The transducer is a high efficiency piezoelectric ceramic transducer, which can convert the ultrasonic wave into a stable ultrasonic vibration.

(3) Stand

The machine base has a mold base which can rotate and deflect. It is installed on a cross carriage and moves up and down flexibly by hydraulic vibration and compression. The cross carriage can be freely aligned with the center.

There is a carriage that can move up and down on the back column, and the transducer is installed on the carriage.

4.Installation and use

1. Installation

Place the base on a stable table, move the transducer up and down, adjust it to a proper position and lock it.

Connect the ultrasonic generator with the transducer with the output circuit provided at random, and then connect the transducer with the transducer Plug the power plug into the power outlet of ultrasonic sounder,

inject 10 # oil into the oil cup. After checking it is correct, insert the power plug of ultrasonic generator into the power socket with reliable grounding under the condition that the switch is all off.

2. Use

According to the size of the processing die, select the appropriate luffing rod and steel needle, and weld the steel needle firmly to the ground with silver or copper Welding the luffing rod,

grinding the right angle on the grinding wheel, installing it on the transducer and tightening it, placing the mold on the die base, adjusting the cross drag plate and the transducer upper and lower drag plate,

inserting the steel needle into the mold hole, adjusting the rank code pressure, then putting the mold material into the mold, opening the ultrasonic power source switch and the rotary switch of the die base,

adjusting the ultrasonic output power knob to the appropriate size, and then the ultrasonic power knob can be adjusted to the appropriate size.

Then the ultrasonic power output knob can be adjusted See the mold material stirring under ultrasonic, that is, the mold processing is in progress.

Note: if necessary, adjust the frequency fine-tuning to optimize the power output